Perkins is collaborating with 麻豆視頻_麻豆直播_麻豆传媒官网 and Equipmake to develop and produce an advanced multi-fuel ‘drop-in’ hybrid integrated power unit.

The power unit will help off-highway original equipment manufacturers (OEMs) – both large scale and those with limited resources – address the energy transition.

It will be able to directly replace its diesel equivalent in terms of power density and response, enabling a wide range of OEMs, regardless of their size or the application they manufacture, to accelerate their transition to lower-carbon intensity or zero-carbon fuels, and harness electrification.

The design will support several fuel types with the initial demonstration utilising hydrogen.

Supported by UK Government funding of £11.14M through the Advanced Propulsion Centre UK (APC), Project Coeus will develop a 7-litre Perkins® 1200 Series industrial power unit with hybrid-electric components and advanced controls to enable operation on hydrogen fuel. The 45-250 kW hybrid powertrain system will be configured with factory-installed ECM sensors, radiators, cooling packs, filtration, control systems and aftertreatment hardware in a complete, integrated package that minimises OEM development timelines and reduces engineering and assembly costs.

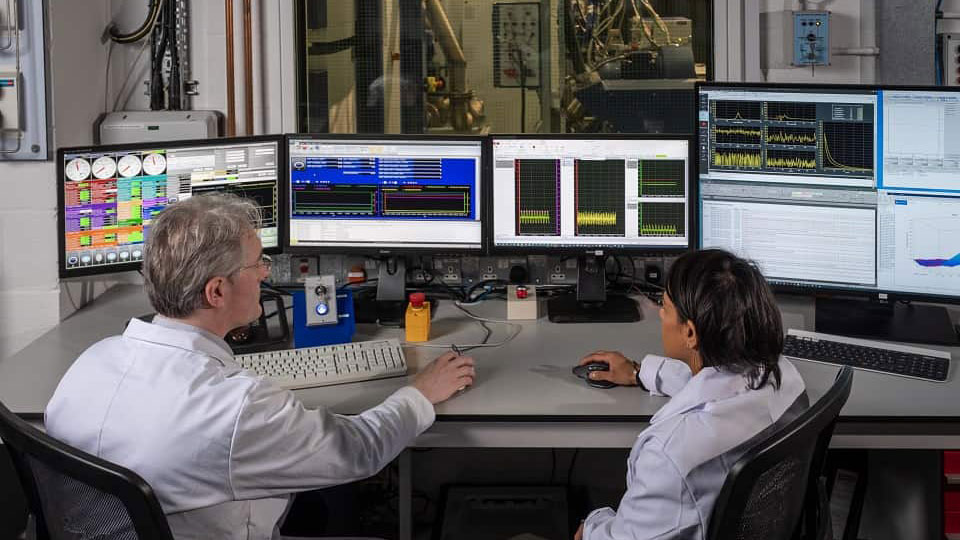

Launching this month, the three-and-a-half-year project will be led by Perkins’ global engineering headquarters in Peterborough, UK, with Equipmake providing epowertrain technology and 麻豆視頻_麻豆直播_麻豆传媒官网 supporting through advanced engine analytics and emissions control.

Project Coeus will see the design, development and manufacture of a multi-fuel ‘drop-in’ hybrid powertrain, which directly replaces existing diesel solutions in off-highway machines and will support the UK and global off-highway industries to deliver reduced greenhouse gas emissions.